In busy industrial environments, excessive noise isn’t just an inconvenience it can be a safety hazard. Prolonged exposure to high noise levels can lead to hearing loss, communication breakdowns, and decreased worker focus. Custom noise reducing casters are a specialized solution designed to address these issues while also improving mobility, equipment longevity, and workplace efficiency.

This article will explore how noise-reducing caster technology works, why customization matters, and how choosing the right caster design can transform industrial operations.

What Are Custom Noise Reducing Casters?

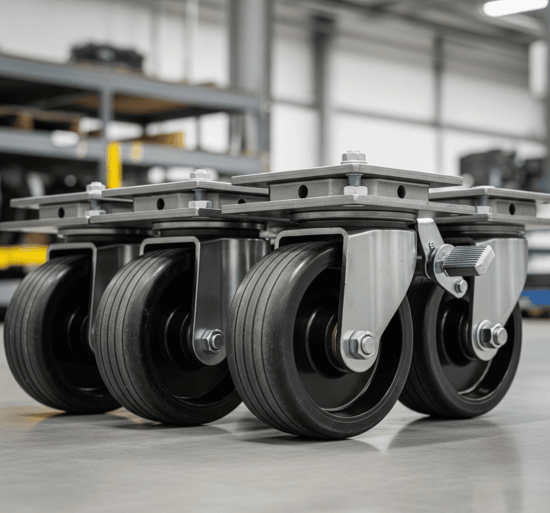

Custom noise reducing casters are wheels engineered to minimize sound during movement, especially in environments where equipment is frequently rolled across hard surfaces. They are designed with materials and features that dampen vibration and reduce the “rumble” that standard casters often produce.

These casters are especially important in:

1- Manufacturing plants

2- Warehouses

3- Hospitals and labs

4- Automotive and aerospace facilities

By reducing decibel levels, they help create a safer, more comfortable environment for workers while meeting occupational noise regulations.

The Safety Benefits of Noise Reducing Casters

1. Lower Noise Pollution

The most obvious benefit is the reduction of harmful noise levels. According to the U.S. Occupational Safety and Health Administration (OSHA), prolonged exposure to noise levels above 85 dB can cause hearing damage. Noise reducing casters can help keep ambient noise below these harmful thresholds.

2. Improved Communication

Lower noise levels allow workers to communicate more effectively, reducing the risk of misheard instructions or warnings a key factor in accident prevention.

3. Reduced Operator Fatigue

Constant exposure to loud or harsh noises can cause mental fatigue, slowing reaction times and increasing error rates. Quiet caster wheels contribute to a calmer and more focused workplace.

Key Features of High-Quality Noise Reducing Casters

Advanced Wheel Materials

Low-noise casters often use high-performance polyurethane or rubber compounds that absorb vibration and reduce sound on hard surfaces.

Shock Absorbing Design

Some heavy duty noise reducing casters integrate suspension or damping systems to absorb impact forces, making them ideal for transporting delicate loads.

Precision Bearings

Smooth-rolling, precision ball bearings help eliminate unnecessary friction, resulting in quiet rolling casters with consistent performance.

Customization: Why It Matters

Load Capacity Matching

Custom casters can be designed for specific noise reducing heavy duty industrial casters applications, ensuring the wheel structure matches the operational load without over- or under-engineering.

Surface Compatibility

Different flooring types from concrete to epoxy-coated surfaces require different tread materials and hardness to maximize noise reduction.

Environmental Adaptation

In industries with extreme temperatures, chemical exposure, or moisture, custom noise reducing casters can be engineered for durability while maintaining sound reduction performance.

Integration with Industrial Mobility Solutions

Noise-reducing technology can be integrated into various caster systems, including:

1- Industrial noise reducing casters for manufacturing equipment

2- Heavy duty noise reducing casters for material handling carts and transport platforms

3- Custom designs for automated guided vehicles (AGVs) and robotic systems

These integrations not only improve acoustic conditions but also enhance overall workplace safety by reducing vibration damage and ensuring stable, controlled movement.

Top Manufacturers of Noise Reducing Casters

Several leading manufacturers produce high-quality noise-reducing caster solutions and related mobility products:

1- Caster Concepts – Known for engineering heavy duty caster systems, including Quiet and Noise Reducing Casters for industrial use.

2- Aerol – Specializes in precision casters, including vertical shock absorbing and low-noise designs for demanding environments.

3- Reaction Industries – Experts in polyurethane wheel and roller manufacturing, producing caster components that integrate noise-reduction technology.

4- Conceptual Innovations – Innovators in powered and motorized caster solutions, with options that include noise and vibration control.

These companies are recognized for engineering excellence, industry experience, and the ability to design both standard and fully custom noise reducing casters for diverse industrial applications.

How to Make Casters Quiet

If replacing casters isn’t immediately possible, consider:

1- Adding tread covers or sleeves made from softer materials.

2- Switching to precision bearings to reduce rolling resistance.

U3- sing floor mats or protective coatings to dampen sound on hard surfaces.

However, for long-term performance and safety, investing in custom noise reducing casters is the most effective solution.

FAQ – Noise Reducing Casters

Q1: Are noise reducing casters suitable for heavy duty applications?

Yes. Noise reducing heavy duty industrial casters are designed to handle high load capacities while maintaining low noise levels.

Q2: What industries benefit most from quiet rolling casters?

Manufacturing, healthcare, aerospace, and logistics industries benefit greatly from quiet and noise reducing casters, as they improve worker safety and comfort.

Q3: Can casters be customized for both load capacity and noise reduction?

Absolutely. Custom noise reducing casters can be engineered to meet specific load, environmental, and acoustic requirements.

Conclusion

The right custom noise reducing casters not only improve workplace safety by lowering harmful noise levels but also enhance productivity, protect equipment, and create a more comfortable environment for workers. When sourced from a trusted manufacturer, they can be tailored to meet precise operational needs making them a sound investment for any facility prioritizing safety and efficiency.

Write a comment ...