When moving heavy equipment across industrial floors or uneven surfaces, stability is everything. That’s where pneumatic locking casters come in. Unlike standard casters, these wheels combine the shock-absorbing benefits of pneumatic tires with the secure stopping power of locking mechanisms. The result? Equipment stays steady, safe, and in place even when dealing with heavy duty pneumatic wheels or loads weighing thousands of pounds.

In this article, we’ll explain what pneumatic locking casters are, how they improve safety, and why they’re the preferred choice for industries handling pneumatic casters heavy duty applications.

What Are Pneumatic Locking Casters?

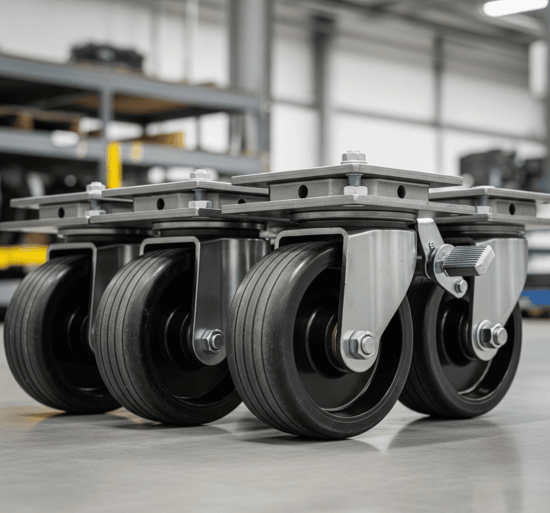

Pneumatic locking casters are industrial wheels designed with an air-filled tire and a built-in brake or lock system. The pneumatic wheel casters provide smooth movement across uneven terrain, while the locking mechanism ensures equipment won’t roll or shift once positioned.

These casters are commonly used on carts, dollies, medical beds, and heavy duty material handling equipment. They are available in multiple sizes, including:

1- 4 inch pneumatic casters (compact applications)

2- 5 inch pneumatic casters

3- 6 inch pneumatic casters / pneumatic casters 6 inch

4- 8 inch pneumatic casters and 8 inch pneumatic swivel casters

5- 10 pneumatic casters

6- 12 inch pneumatic casters for oversized equipment

Why Stability Matters with Heavy Loads

In manufacturing and logistics, shifting loads can cause downtime, damage, or even workplace injuries. Using locking pneumatic casters reduces this risk by keeping equipment firmly in place. This is especially critical when dealing with:

1- 1000 lb pneumatic casters for high-capacity loads

2- dual pneumatic casters or dual wheel pneumatic casters for wide, bulky equipment

3- heavy duty pneumatic caster wheels designed for rugged performance

The locking function prevents accidental rolling, ensuring both operators and equipment remain safe.

Key Benefits of Pneumatic Locking Casters

1. Enhanced Safety

Locking systems minimize risks of carts rolling unexpectedly, particularly in sloped or uneven environments.

2. Shock Absorption

Like standard pneumatic casters wheels, locking models cushion vibrations and reduce stress on floors, making them ideal for sensitive equipment.

3. Heavy Duty Load Capacity

With options like pneumatic casters heavy duty and heavy duty pneumatic wheel casters, they can handle demanding industrial applications, including loads exceeding 1,000 lbs.

4. Versatility Across Industries

From aerospace assembly lines to medical transport systems, pneumatic casters with brakes are adaptable to diverse environments.

Types of Pneumatic Locking Casters

Heavy Duty Pneumatic Wheel Casters

Built for strength, these heavy duty pneumatic castor wheels carry massive loads while maintaining mobility.

Pneumatic Swivel Casters with Locks

The swivel function improves maneuverability, while the lock secures positioning perfect for assembly operations requiring precision.

Small Pneumatic Casters with Brakes

Small pneumatic casters (such as 4 inch diameter pneumatic casters) are ideal for lighter carts, offering stability without compromising portability.

Dual Wheel Pneumatic Casters

Designed for ultra-heavy loads, dual pneumatic casters distribute weight evenly, improving balance and control.

Applications of Pneumatic Locking Casters

1- Manufacturing & Warehousing

Used on material handling carts and workstations to stabilize heavy components during production.

2- Healthcare

Pneumatic casters with brakes ensure patient beds and medical equipment stay securely in place.

3- Aerospace & Defense

Precision assembly demands stable platforms, making locking pneumatic casters a necessity.

4- Outdoor & Rough Terrain Use

Air-filled pneumatic tires casters handle gravel, asphalt, and uneven outdoor surfaces with ease.

Choosing the Right Pneumatic Locking Casters

When selecting pneumatic casters, consider:

1- Load capacity: From 4 pneumatic casters for light carts to 1000 lb pneumatic casters for industrial machinery.

2- Caster size: Larger sizes like 12 inch pneumatic casters provide smoother travel over rough terrain.

3- Swivel vs. rigid: Choose pneumatic swivel casters for maneuverability or fixed casters for straight-line stability.

4- Locking mechanism: Ensure the brakes are reliable enough for your load requirements.

FAQ: Pneumatic Locking Casters

Q1: What is the difference between pneumatic casters and solid casters?

Pneumatic casters use air-filled tires, providing cushioning and better terrain adaptability. Solid casters are harder and better suited for smooth indoor surfaces.

Q2: Can pneumatic locking casters handle over 1,000 lbs?

Yes. Many heavy duty pneumatic caster wheels are rated for loads exceeding 1,000 lbs, especially when using dual wheel pneumatic casters.

Q3: Do pneumatic casters with brakes work on sloped floors?

Yes, but it’s important to choose high-quality locking mechanisms for secure stability on inclines.

Conclusion

Pneumatic locking casters deliver the perfect balance of smooth mobility and secure stability for industrial applications. Whether you’re moving sensitive equipment, stabilizing heavy machinery, or working on uneven terrain, these casters offer unmatched safety and performance.

By investing in the right caster type whether 8 pneumatic casters, dual pneumatic casters, or 12 inch pneumatic casters you can protect your equipment, floors, and workers while improving efficiency.

Write a comment ...